Two-Shot Injection Molding

Two-Shot Injection Molding:

Two-Shot Injection Molding may also be referred to as: bi-injection molding, co-injection Molding, or Multi-Shot Injection Molding

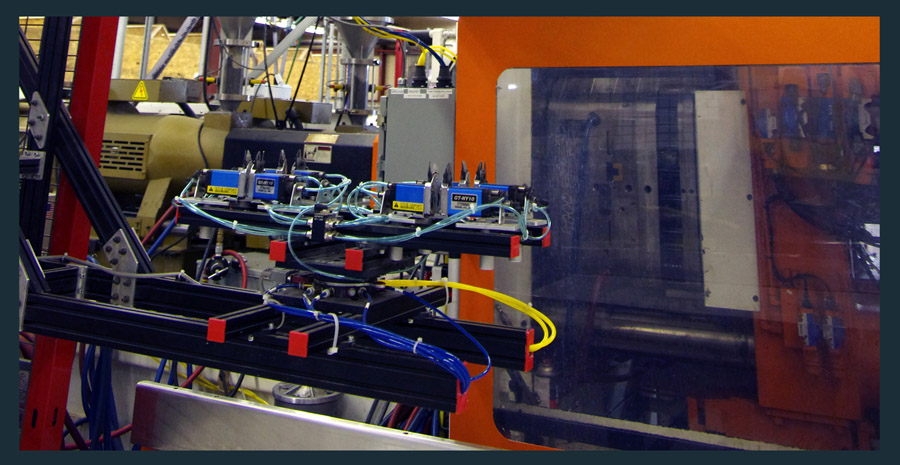

This technology produces a part with two different raw materials and/or colors in a single operation. The machine has two injection units: one vertical and one horizontal. By using a rotating mold, the machine automatically produces a substrate of one resin or color and overmolds the part with the second resin or color.

Triad Fastener provides Two-Shot and Two-Color Injection Molding for a variety of industries. Typically, Two-Shot Injection Molding is used for soft-touch over-molding grips in power tools, outdoor equipment, medical equipment, electrical equipment, consumer products, and automotive components. This process reduces part costs by eliminating labor, improving quality, and eliminating post-molding steps such as sonic welding, assembly, snap fits or fasteners. The cost advantages become obvious, especially when applied to high volume parts.

Advantages over alternative methods:

- Insert molding and complex secondary operations are eliminated.

- Painting (which can rub off) is eliminated.

Check out our new Quality Control room.

Check out our new Quality Control room.