Horiztonal Injection Molding

Horizontal Injection Molding

Horizontal Injection Molding

Horizontal Injection Molding machines are the most widely used plastics machines in the world.

Triad Fastener has experience and expertise to take your project from the design phase all the way through production. We can help determine which of our molding processes and materials is right for meeting your specifications.

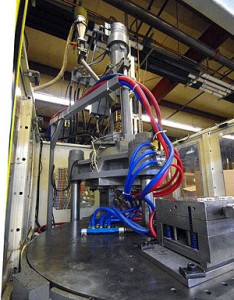

Vertical Injection Molding

Check out our new Quality Control room.

Check out our new Quality Control room.